As pluggable I/O data rates and bandwidth continue to increase, power consumption and heat generation are inevitably rising as well, causing adverse effects on high speed product’s performance and reliability. This is especially critical when it comes to 5G era when thermal performance has become one of the most challenging issues to be solved. This challenge is fully reflected in form factors such as QSFP-DD where thermal performance has great impact on overall high speed quality.

There are various methods for thermal enhancement, just to name some – more vent holes, leveraging heat pipe, changing heat sink to zipper fins, and applying graphene and thermal pad. Each one of them has pros and cons depending on the environment in which the product operates.

Nextron wants to share two of effective ways – Zipper Fin and Heat Pipe – to thermal enhancement, both of which optimize thermal performance by integrating system requirements such as air flow and mechnical fitting into overall design.

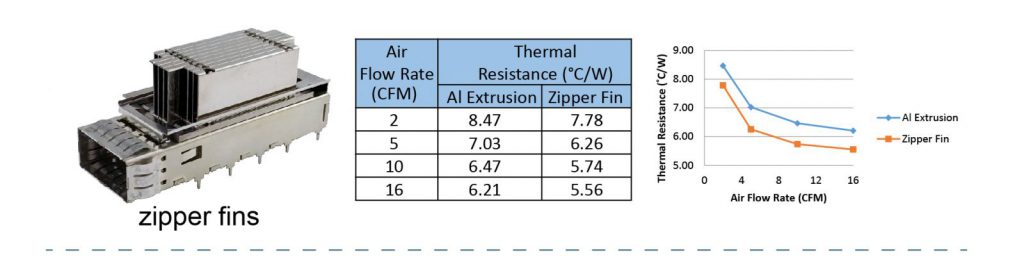

ZIPPER FIN

Aluminum extrusion fin’s height to width ratio is 20 at maximum due to limitation in manufacturing method, while zipper fin can reach such ratio to 40 at top. Heat sink’s heat dissipating performance relies on fin area, the more the better. In the same base width, smaller fin width can generate more number of fins for heat dissipation. For extrusion, minimum fin width is 0.5mm whereas zipper fin can be as little as 0.1mm.

In this case, Nextron compares heat sinks of extrusion and zipper fins both with 0.5mm fin in width and their extreme heights of 7.5mm and 20mm respectively. The result is that thermal resistance of zipper fin is 8.1% lower than aluminum extrusion at 2 CFM air flow condition. This shows that zipper fin can be a great way to enhance thermal performance by creating more surface area for heat dissipation.

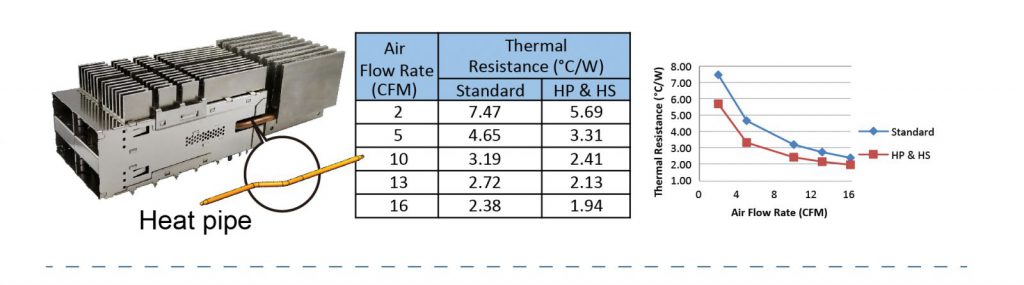

HEAT PIPE

Heat pipe is highly efficient in transferring heat from heat source to the cooling area, which is usually connected to customized heat sink. Combo cage generates more heat than one row cage due to its compact nature, therefore combo cage’s thermal enhancement is very critical for 5G and higher era to come.

Nextron demonstrates heat pipe solution’s effectiveness with our unique customized design our unique customized design. The design concept is to insert metal block in between two layers to conduct heat from transceiver to the customized heat sink placed in the back of cage, through heat pipes that connect between metal block and customized heat sink. The result shows that customized heat pipe with back heat sink’s thermal

performance is enhanced by 23.9% at as low air flow as 2 CFM, which is a great improvement from standard solution. Nextron has the capability to maximize thermal performance by exploiting available space in the system, to provide effective solutions that work for our valuable customers.

Nextron has long experience working with worldwide major brands for solving thermal issues. With in-house simulation software such as SolidWorks and test equipment like wind-tunnel, Nextron is dedicated that our thermal solutions go through a series of reliability check to ensure qualified products. Having proven success in product development and experienced engineering teams, Nextron strives for designing and realizing custom thermal solutions for customers at the best price comparing to competitors.

Source from : Nextronics Engineering Corp.